Written by

Melanie MarchHow to Spot Transport Trailer Electrical Issues

Electrical problems in transport trailers can range from minor inconveniences to critical issues that impact safety and functionality. These problems can occur due to wear and tear, environmental factors, or manufacturing defects.

Common electrical problems include:

- BURNT-OUT BULBS

Trailer lighting is essential for road safety. Burnt out bulbs in brake lights, turn signals, marker lights, and interior lighting can reduce visibility and increase the risk of accidents. - FAULTY WIRING

Damaged or frayed wires can disrupt electrical connections, leading to intermittent or complete failures in various trailer systems. This may include issues with brakes, lights, or other critical components. - CORROSION

Exposure to the elements, especially in areas with harsh weather conditions, can cause corrosion in electrical connectors and wires. Corrosion can result in poor electrical connections and signal loss. - BATTERY PROBLEMS

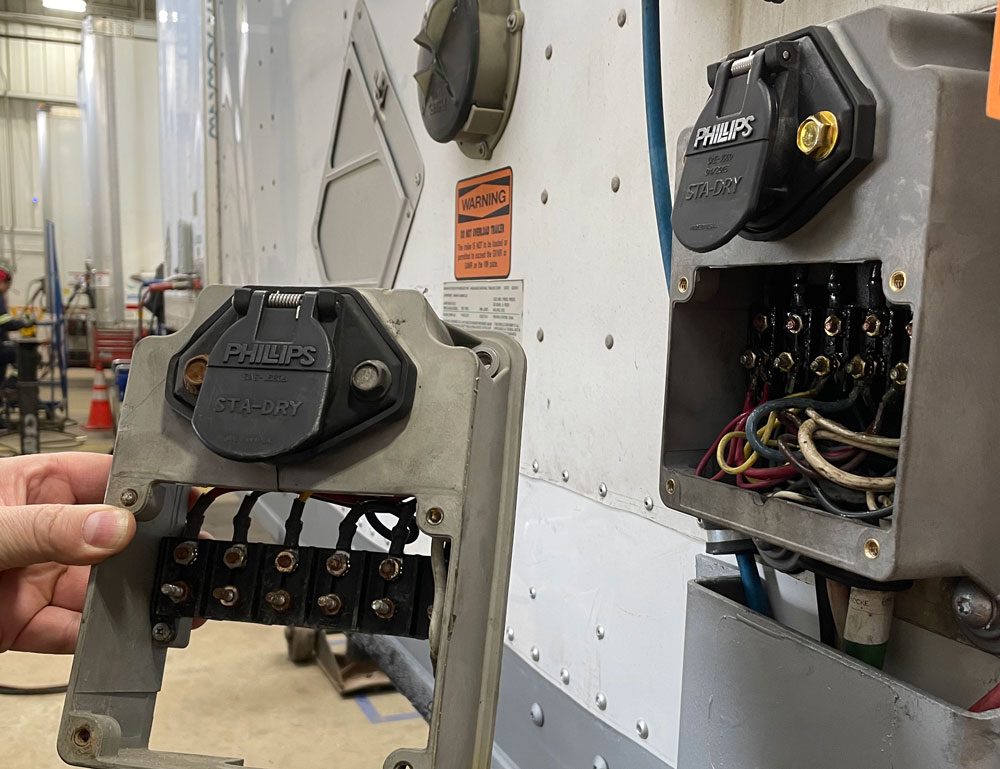

Transport trailers often have batteries to power internal and external systems. Battery problems, such as dead or drained batteries, can impact the trailer’s ability to power refrigeration units, lift gates, or interior appliances. - FAULTY CONNECTORS

Connectors, such as the 7-way round or 7-way blade plug, can become damaged or corroded or worn. This can disrupt the electrical connection between the trailer and the tractor, affecting all aspects of the trailers wiring system including but not limited to the brake lights, turn signals, ABS system and tail or marker lights, brake lights, turn signals, and power supply. - FAULTY TRAILER ABS (Anti-lock Braking System)

ABS sensors and wiring can develop issues, leading to a malfunction of the ABS system. Properly functioning ABS is crucial for maintaining control during emergency hard braking. - TRAILER REEFER UNIT ISSUES

Refrigerated trailers (reefers) rely on electrical systems to maintain temperature control. Problems in these systems can lead to spoilage of goods or temperature fluctuations. - TRAILER TIRE INFLATION SYSTEMS

Many modern transport trailers are equipped with tire pressure monitoring systems (TPMS) that rely on electrical components. Failure in these systems can lead to under-inflated tires and reduced fuel efficiency. - INTERIOR ELECTRICAL SYSTEMS

Inside the trailer, issues may arise with lighting, climate control, and appliances. These problems can impact the comfort and safety of drivers and the integrity of transported goods. - TELEMATICS AND TRACKING SYSTEMS

Many transport trailers are equipped with GPS and telematics systems for tracking and monitoring. Electrical problems in these systems can disrupt fleet management and security.

To prevent electrical problems in transport trailers, regular maintenance and inspections are crucial. Routine Pre-Trip Circle Checks, along with immediate repairs when issues are identified, can help ensure that trailers remain in safe and working condition. Additionally, quality electrical components and proper weatherproofing can help minimize the risk of electrical failures due to environmental factors.

Featured

TEN Announces Pricing Of Offering Of $700 Million Principal Amount Of Secured Second Lien Notes Due 2030

TRENDING ARTICLES

Episode 2: TEN x ACT Research: Fireside Chat Recap– Navigating Market Uncertainty & Fleet Trends

TEN and ACT Research Launch First Episode in Fireside Chat Series

TEN Announces Pricing Of Offering Of $700 Million Principal Amount Of Secured Second Lien Notes Due 2030

CATEGORIES

TEN

TEN Cool