Written by

Melanie MarchUnderstanding the Lifecycle of a Trailer: Key Maintenance Milestones

Like any high-performance equipment, trailers endure wear and tear over time. Understanding where and when that wear occurs is essential to ensuring safety, operational efficiency, and long-term asset value.

Below is a breakdown of key maintenance milestones across a trailer’s lifecycle and how proactive maintenance programs can reduce downtime and extend equipment life.

Common Lifecycle Stages & Service Needs

Although usage patterns vary, most trailers follow a predictable maintenance trajectory. Key service intervals include:

1. Early Use (1–3 Years): Establishing a Maintenance Baseline

- Focus: Inspections, lubrication, and minor adjustments

- Typical Tasks: Preventive maintenance inspections, torque verifications

- Why It Matters: Early-stage maintenance establishes proactive habits that help catch issues before they become costly repairs.

2. Mid-Life Wear (4–7 Years): First Signs of Component Fatigue

- Focus: Monitoring high-use systems for early wear

- Typical Tasks: Tire replacements, door alignments, brake replacements

- Why It Matters: Components such as brakes, doors, and air ride systems begin to degrade. Timely intervention prevents failures and unexpected downtime.

3. Long-Term Usage (8–12 Years): Structural and System Integrity

- Focus: Core structural and electrical system health

- Typical Tasks: Floor repairs, corrosion prevention, bushing inspections

- Why It Matters: At this stage, wear impacts the trailer’s integrity. Planned repairs extend usability and avoid major capital investments.

4. Mature Equipment (15+ Years): Reconditioning & Replacement Planning

- Focus: Major refurbishment and lifecycle decision-making

- Typical Tasks: Corrosion remediation, replacement of high-wear components

- Why It Matters: Fleets must evaluate whether to continue investment in older equipment or decommission and replace.

The Role of Preventive Maintenance

Preventive maintenance isn’t about reacting to failures – it’s about avoiding them altogether. Benefits of a structured preventive program include:

- Reduced emergency repairs and roadside breakdowns

- Enhanced safety and regulatory compliance (e.g., DOT inspections)

- Prolonged trailer lifespan

- Controlled maintenance spend with predictable service costs

A proactive strategy includes routine checklists, digital service history tracking, and scheduling based on usage patterns and trailer type.

Conclusion: Managing the Full Lifecycle

Maximizing trailer performance requires aligning service strategies with known wear intervals. Whether managing dry vans, reefers, or specialty trailers, implementing a disciplined maintenance approach ensures cost-effective, long-lasting operation.

Featured

TEN Acquires Boston Trailer, Strengthening Position as Leading Trailer Lessor Across North America

TRENDING ARTICLES

Understanding the Lifecycle of a Trailer: Key Maintenance Milestones

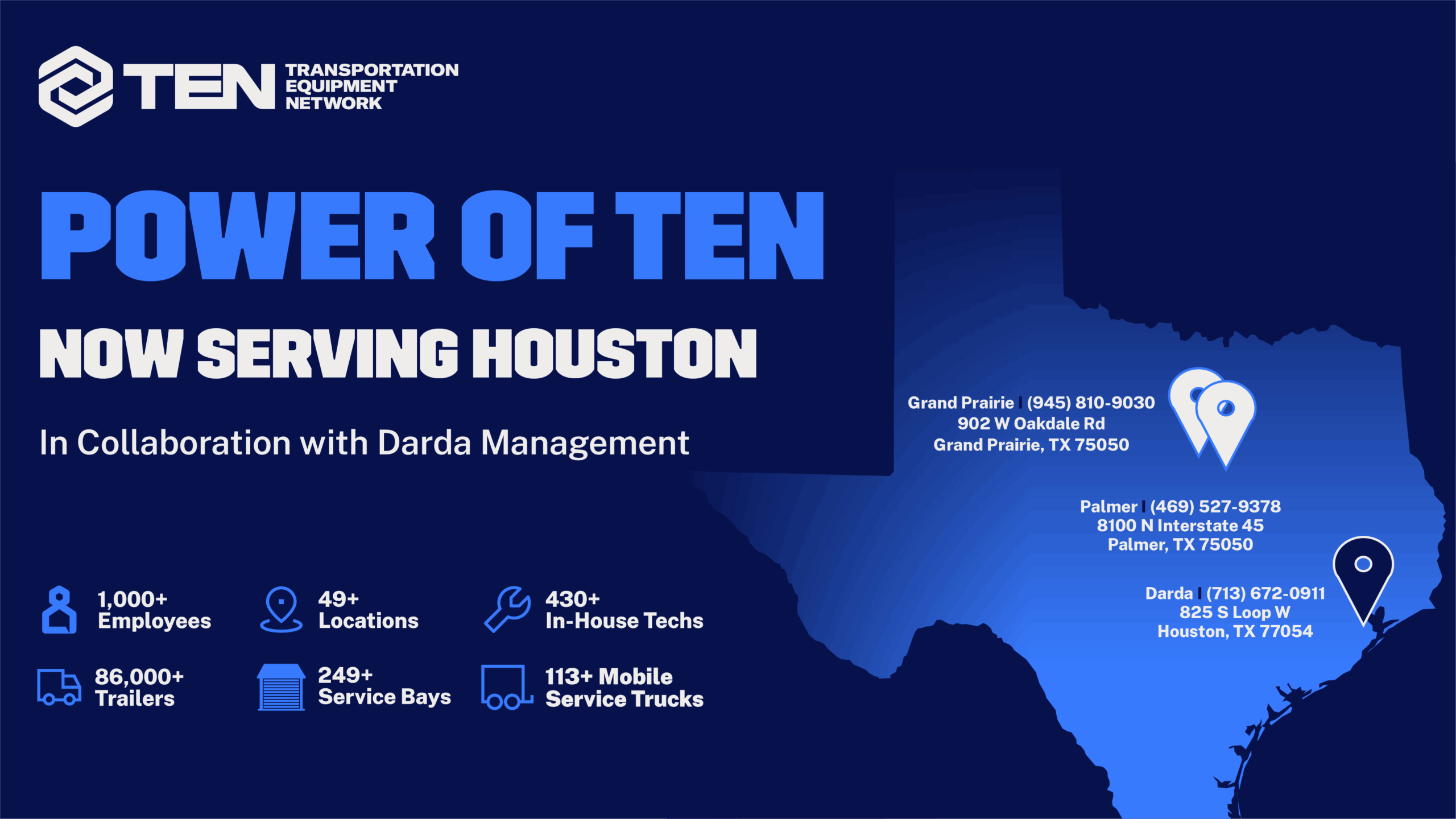

TEN (Transportation Equipment Network) Launches in the Houston Market in Collaboration with Darda Management Group

Emergency Roadside Assistance vs. Full-Service Maintenance for Trailer Leasing: What’s the Difference?

CATEGORIES

TEN

TEN Cool